What do you know about Paper Converting?

The Paper Converting Process

The logistical headache you can avoid and waste reductions you can enjoy!

Not many people understand “paper converting,” but it is an essential part of the process for taking raw paper and making a finished product.

The basics of the paper converting process include

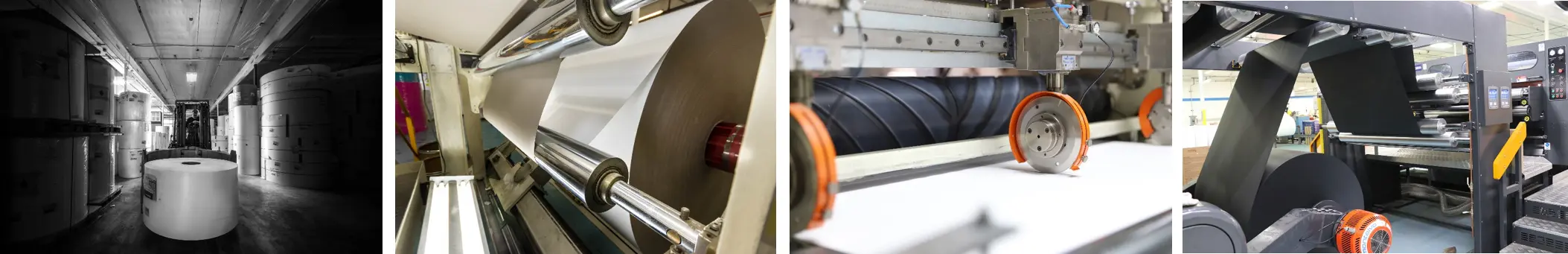

- Paper made from trees or wood fibers use raw wood that melts into “pulp.” This pulp is bleached, strained, flattened, and dried in a process that yields a continuous roll of paper.

- The master roll of paper is transformed and cut to the desired size. This process of cutting the rolls down is called “converting.”

- Converting these large rolls into smaller sizes consists of many different phases, but it’s an essential part of the process of making the finished product. Since there are many different sized printing presses, changing the roll’s width or diameter is required to accommodate a particular printing press.

Types of converting processes

The Slitter or rewinder is the most commonly used type of converting process. This process (self-explanatory in the name) takes the large rolls and unwinds the paper through a series of blades that cut the paper into smaller widths and rewinds the paper into the new rolls to desired measurements.

Another converting type is the precision paper roll saw that cuts the master paper roll without the unwinding and rewinding.

Norka’s in-house paper converting process means that our team of printers and designers can create the perfect sheet sizes for custom orders. We perfect the layout and sheet size to maximize product output while minimizing scrap and wasted paper fully. By reducing waste and carefully monitoring quality, we can significantly reduce the cost of printing, especially for orders that require specialty papers.

Extensive In-House Paper Converting Capabilities include:

- Trimming

- Die Cutting

- Perfing

- Scoring

- Hole Punching

- Folding

- Gluing and Adhesive Application

- Customized, Non-Standard Cutting

Contact Our Team of Experts to Get Started Today!

Learn more about our two million square feet of production and distribution space, explore our capabilities and services, or connect with our experienced project teams to get started today!